Recepto™ Mechanical Ventilation Heat Recovery (MVHR) Units from Frenger® are amongst the highest efficiency units available on the market, but also with shallow depth construction.

The Standard MVHR unit is designed to provide energy savings for a wide variety of applications, predominately for Schools, Academies, Universities and Offices or any space that requires mechanical ventilation (fresh air) whilst retaining most (up to 94% efficiency) of the heat from the extract air.

Note: For more compact and restrictive applications, such as office meeting rooms and domestic installations, Frenger® offers the Recepto™ Mini MVHR Unit.

The units transfer heat from extracted room air, via the use of a Eurovent certified aluminium static heat exchanger, to the fresh air supply with an efficiency of up to 94%.

MVHR units are high-efficiency static exchangers featuring aluminium plates with countercurrent exchange. The achievable efficiency can exceed 90% because they ensure the transfer of countercurrent heat between two air flows with different inlet temperatures.

The shallow construction depth is due to Frenger's Recepto™ MVHR units having angle mounted centrifugal fans, which are low noise and more efficient than typical fans.

Construction

The external casing is made from 24mm double skin panels, using galvanised steel sheets pre-insulated with polyurethane foam (density 45 kg/m³). The foam uses a water based foaming agent (GWP-0). This construction allows for low noise levels.

The plug-type centrifugal fan for supply and return with an electronically controlled (EC) permanent magnet synchronous motor, supply voltage 230V 50Hz. The impellers are designed to ensure minimal noise and optimal airflow.

The air intake circuits use F7 (fine filtration efficiency) 98mm thick air filters with pleated microcells and M6 (average) for the exhaust circuit. These are sized to minimise pressure drops and are accessed by openings in the side of the unit for easy access. The Recepto™ Standard units are fitted with air pressure switches to indicate when the filters require replacement.

The onboard electrical panel is accessible on the side of the unit. This panel includes the line fuse and electronic power board for the manual or automatic control of the operation of fans and air treatment accessories. The remote control features a display and capacitive-type touch keyboard.

In-House Project Specific Testing

Both of Frenger's Recepto™ Standard and Mini MVHR units offer some of the lowest noise levels available on the market currently, with Frenger's in-house Acoustic testing facility at their UK technical facility allowing for optimisation of product noise levels during operation.

Frenger's HVAC products also undergo third-party acoustic testing to verify all sound power levels. The Acoustic Testing laboratory that can be seen below is their in-house hemi-anechoic chamber, which utilises sound absorbing acoustic foam material in the shape of wedges to provide an echo free zone for acoustic measurements.

Along with Acoustic Testing capabilities, Frenger® also have 3x in-house Climatic Test Laboratories and 2x in-house Photometric Test Laboratories to provide complete Project Specific Testing.

The 3x state-of-the-art in-house Climatic Test Laboratories, which have internal dimensions of 6.3 x 5.7 x 3.2m, feature a thermal wall so that both internal and perimeter zones can be tested as well as simulating internal & external heat gains and losses. The Climatic Test facilities are fixed in overall size and construction and can facilitate both Steady and Non-Steady State Testing

'Dim men' are then placed in predetermined positions around the laboratory to simulate the small heat gains produced by office equipment such as computers or printers.

The two Photometric test laboratories at Frenger's UK technical and manufacturing facility are used to evaluate the performance of luminaires. To measure the performance, it is necessary to obtain values of the light intensity distribution from the luminaire and efficacy.

The intensity distribution is obtained by the use of a Goniophotometer, which measures the intensity of light emitted from the surface of the fitting at pre-determined angles.

The light intensity is then measured using either a photometer with a corrective spectral response filter to match the CIE standard observer curves or our spectrometer for LED sources. Frenger's Integration lab is used to determine the LOR (Light Output Ratio) and efficacy.

These light intensity distributions are used to mathematically model the lighting distribution envelope of a particular luminaire. Frenger® conduct photometric tests in accordance with CIE 127:2007 and BS EN 13032-1 and sound engineering practice as applicable.

Mechanical Ventilation Heat Recovery Unit Accessories

Electric Antifreeze

Frenger's Electric Antifreeze Heating Coil is designed to be situated along the external intake ducting to pre-heat supply air before it reaches the Recepto™ Mechanical Ventilation Heat Recovery units to prevent the heat exchanger from freezing.

The unit is constructed from galvanised sheet metal with a circular duct section that includes rubber gasket to reduce air leakage. Contained within the duct section is an armoured heating element.

The Antifreeze Heating Coil can operate at a temperature range of -20°C to +40°C and features a double safety thermostat (one automatic and one manual reset). The unit has a control board with PWM modulating logic based on the external and exhaust temperature. Protection class IP 43.

Cooling Coil

Frenger's Cooling Coil is designed to be situated along the supply air ducting after the Recepto™ Mechanical Ventilation Heat Recovery unit to provide additional cooling or post heating.

The unit is constructed from galvanised sheet metal with external insulation and flanged duct connections. The internal finned coil cooling battery consists of aluminium fins and expanded copper tubes with exposed brass manifolds/connections.

External 16mm condensation drains connect to a condensate collection tray.

Electric Post Heating Coil

Frenger's Electric Post Heating Coil is designed to be situated along the supply air ducting after the Recepto™ Mechanical Ventilation Heat Recovery unit to provide additional heating.

The coil unit is constructed from galvanised steel metal with a circular duct section that includes a rubber gasket to reduce air leakage. Contained within the duct section is an armoured heating element.

The Post Heating Coil can operate at a temperature range of -20°C to +40°C and features a double safety thermostat (one automatic and one manual reset). The unit is controlled by the ON/OFF logic according to the ambient air temperature, the resistance supply circuit is fitted with an adjustable thermostat which has a limiting function. Protection class IP 43.

Key Features

- High thermal efficiency (Up to 94%)

- Shallow depth (as little as 344mm deep)

- Low noise levels

- Double skin insulated construction to meet the acoustic requirements of BB93

- Less than 1% air leakage

- F7 (fine filtration efficiency) 98mm thick air filters with pleated micro cells as standard, to meet air filtration industry guidelines (Building Bulletin 101). All performance data provided includes the use of filters

- Eurovent certified aluminium heat exchanger

- Low SFP due to unique fan design

- Fully compliant with ErP requirements in the Eco Design Directive

- Freecool setting to allow air to bypass heat exchanger, providing supply air at outside temperature.

- Optional touch screen controller

- Heating and Cooling can be provided with optional accessories

- Fully reversible handing due to symmetrical configuration. This allows air circuits to be easily inverted to change handing on site (one unit can be either handing)

Recepto™ Mini MVHR Unit

Our other units

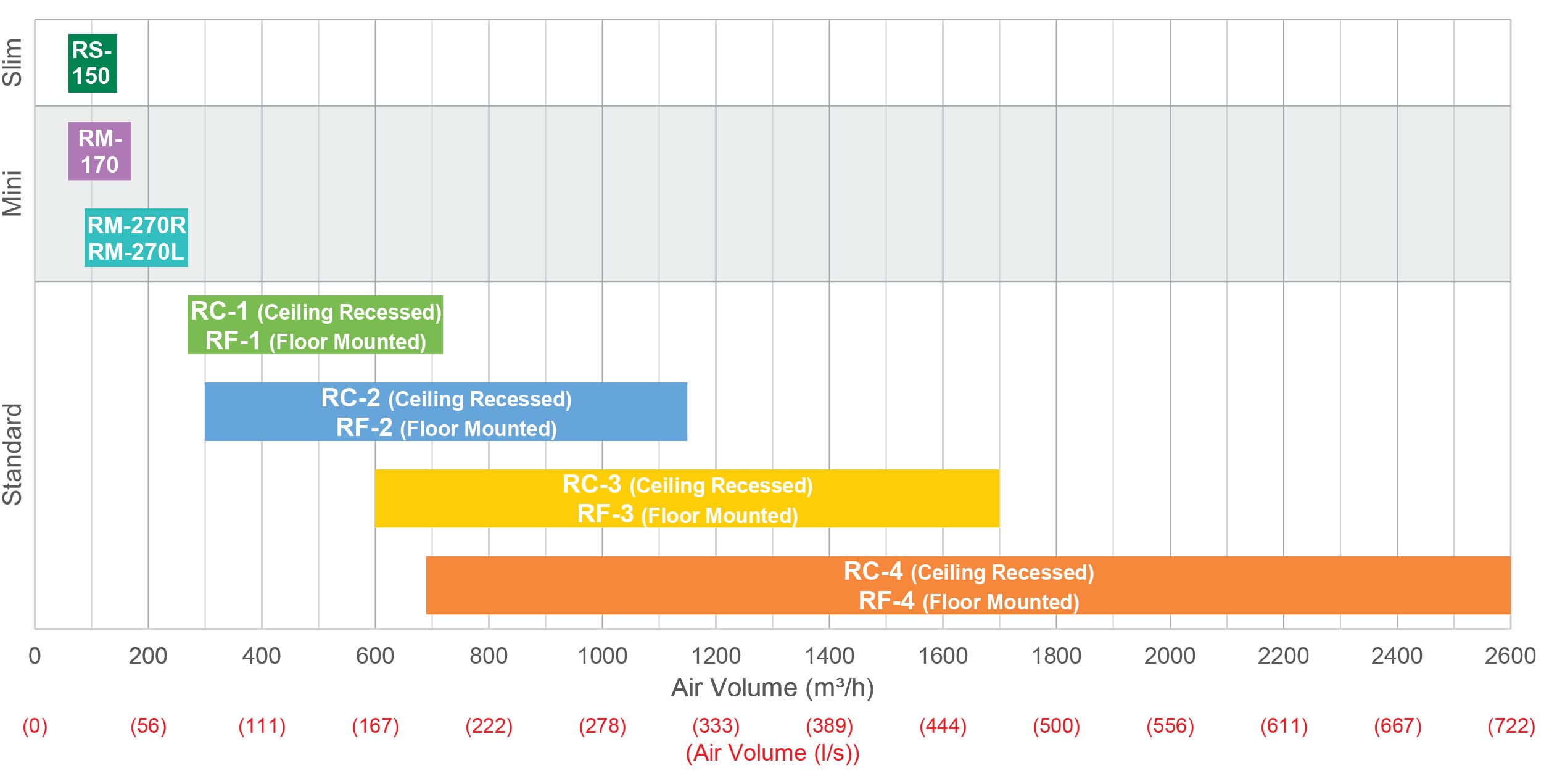

Recepto™ Slim MVHR Units

For applications that require thinner depth, with a Thermal Efficiency (up to 87%). The unit can be Ceiling Recessed or Floor Mounted to suit the parameters of

design teams.

Recepto™ Mini MVHR Units

For more restricted applications that require lower volumes and lower Thermal Efficiency (up to 88%). The unit can be Ceiling Recessed or Floor Mounted to suit the parameters of design teams.

Learn MoreIf you require any further information, or have a project to discuss, please contact us on +44(0)1332 295 678 or sales@frenger.co.uk as our technical team are here to assist.

Thanks for downloading!

Have a question about one of our products or have a project to discuss? Enter your email below and one of our Technical Advisors will be in contact to help with any queries you may have.

Thanks for downloading!

Have a question about one of our products or have a project to discuss? Enter your email below and one of our Technical Advisors will be in contact to help with any queries you may have.

Thanks for downloading!

Have a question about one of our products or have a project to discuss? Enter your email below and one of our Technical Advisors will be in contact to help with any queries you may have.

Thanks for downloading!

Have a question about one of our products or have a project to discuss? Enter your email below and one of our Technical Advisors will be in contact to help with any queries you may have.

Thanks for downloading!

Have a question about one of our products or have a project to discuss? Enter your email below and one of our Technical Advisors will be in contact to help with any queries you may have.